Revolutionizing Hard Tissue Sample Preparation

The recovery of genetic material from skeletal remains is a cornerstone of forensic identification, yet the initial step of hard tissue processing has long been a manual, time-consuming, and contamination-prone bottleneck. The Automated Forensic Bone & Teeth Grinder represents a paradigm shift in DNA extraction preparation, transforming this critical phase into a rapid, standardized, and highly reliable automated process. Engineered specifically for the demands of forensic science, this instrument is designed to efficiently pulverize teeth and dense bone fragments into a fine, homogeneous powder, creating the optimal substrate for downstream DNA isolation. By automating this foundational step, laboratories can achieve greater consistency, higher throughput, and significantly improved DNA yields from their most challenging samples.

Core Advantages: Precision, Purity, and Proven Performance

The design philosophy of this instrument centers on delivering uncompromising results where it matters most: sample integrity and analyst safety. It replaces variable manual techniques with a standardized, automated grinding process that guarantees consistency from one sample to the next. Every engineering decision, from the sealed grinding chamber to the disposable grinding chamber consumables, is made to uphold the principles of contamination-free operation and high efficiency. This results in a system that not only protects the delicate DNA within the sample but also safeguards the laboratory environment and its personnel, establishing a new benchmark for reliable hard tissue processing.

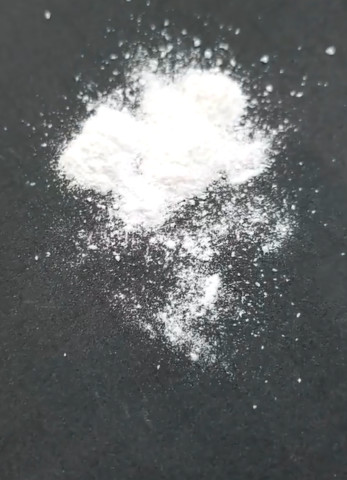

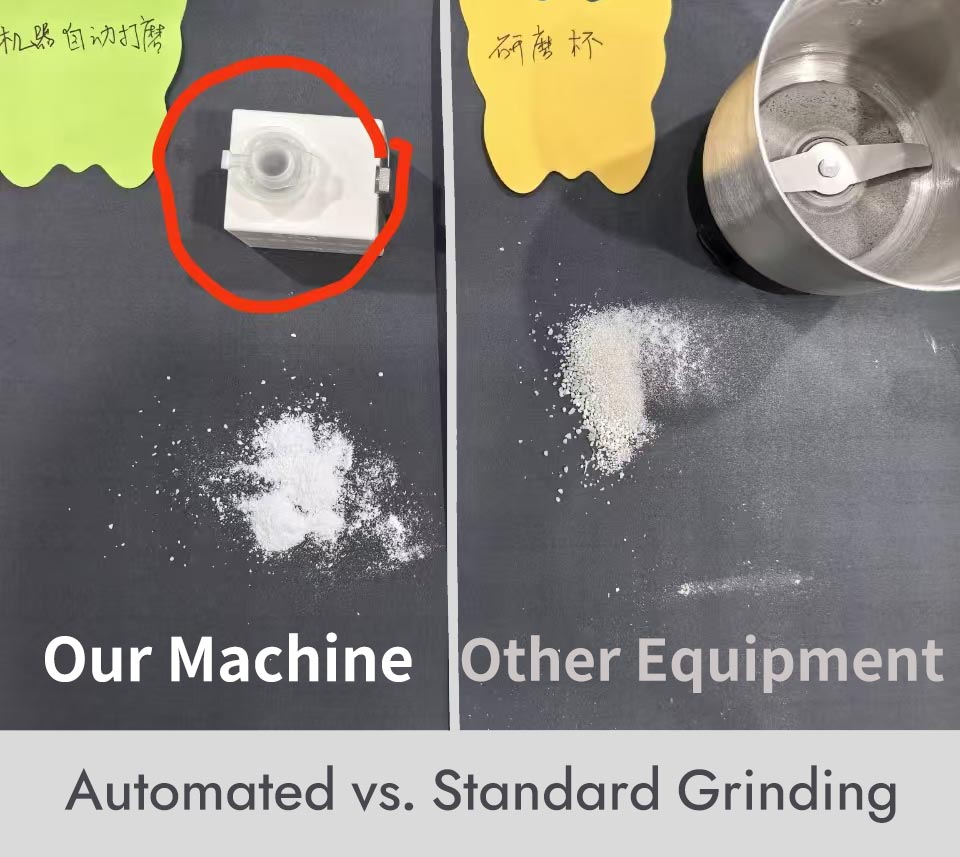

Rapid & Efficient Processing: Complete Sample in 120-200 Seconds

Time-saving automation is a key benefit. The instrument completes a full grinding cycle, transforming a tooth or bone fragment into a fine powder, in approximately two to three minutes. This fast grinding capability stands in stark contrast to the lengthy and physically demanding process of manual crushing with a mortar and pestle or the inconsistent results from other mechanical mills. This high throughput directly translates to increased laboratory productivity, allowing analysts to prepare more samples for extraction in a single shift and accelerating the overall timeline for identification projects, from historical remains to active missing persons cases.

No Heat Generation: Preserves DNA Integrity During Pulverization

A critical concern during mechanical grinding is the generation of frictional heat, which can denature and fragment DNA, reducing both yield and quality. Our system employs an advanced cryogenic grinding mechanism that ensures a consistently low-temperature process throughout the operation. By effectively preventing heat buildup, the technology safeguards the DNA degradation prevention, preserving the length and integrity of the DNA strands. This is especially crucial for already degraded forensic samples, where every intact molecule counts, ensuring that the maximum amount of genetic information is preserved for subsequent STR amplification or next-generation sequencing.

Zero Cross-Contamination: 100% Single-Source DNA Recovery with Disposable Cassettes

The most significant risk in forensic sample processing is cross-contamination between cases. This system eliminates that risk through a revolutionary single-use design. Each sample is placed into its own dedicated, pre-sterilized disposable grinding cassette. This cassette is the only component that contacts the sample. After grinding, the entire cassette, now containing the powdered sample, is removed. The grinding chamber itself never comes into contact with biological material, making thorough cleaning between runs unnecessary and guaranteeing 100% single-source DNA recovery. This approach represents the gold standard in cross-contamination prevention for forensic genetics.

Sealed & Safe Operation: Closed System Eliminates Biohazard Exposure

Laboratory safety is paramount when processing potentially hazardous biological materials. The grinding process occurs entirely within a sealed, robust grinding chamber. This closed system design ensures that no powder aerosol or bone dust is released into the laboratory environment during operation. Analysts are protected from inhaling particulate matter, and the risk of contaminating other workspaces or evidence is nullified. This feature not only protects personnel but also upholds the stringent clean lab standards required for sensitive DNA analysis, making the instrument safe for use in open laboratory settings.

Intelligent Operation: 10-Inch Touchscreen, Barcode Scanner, and Data Export

The instrument is controlled via an intuitive 10-inch color touchscreen user interface, requiring minimal training. For seamless sample tracking and chain of custody, an integrated barcode scanner allows the technician to scan the sample ID directly from the cassette or associated paperwork at the start of the cycle. All process data, including sample ID, date, time, and cycle parameters, is logged. This data can be easily exported via USB or Ethernet connection to a laboratory information management system (LIMS) or external drive, providing a digital audit trail and simplifying laboratory record-keeping.

Reliable & Compliant: Bilingual Interface and Automatic Audit Trail (4000+ Records)

Designed for global forensic use, the system features a fully bilingual interface (Chinese/English) that can be switched with a single touch. Internally, the instrument maintains a robust, non-volatile memory capable of storing detailed audit logs for over 4000 grinding cycles. Each log entry includes a timestamp, user ID, sample ID, and cycle parameters.

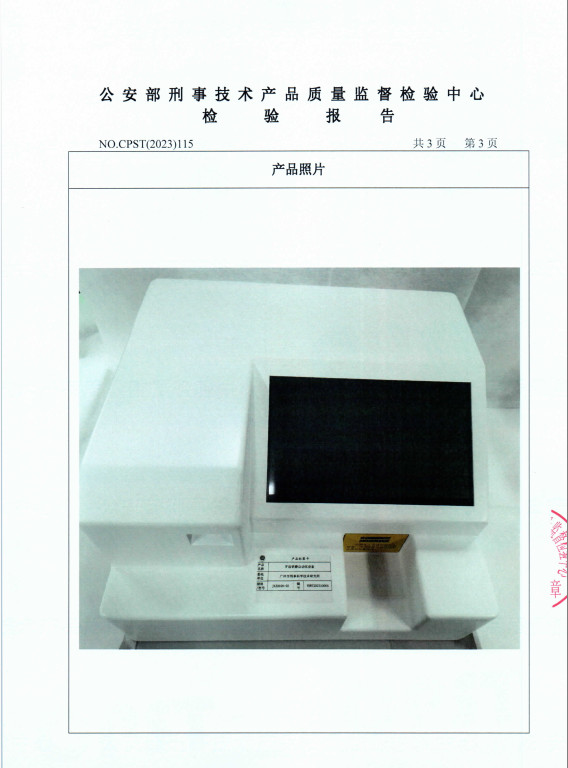

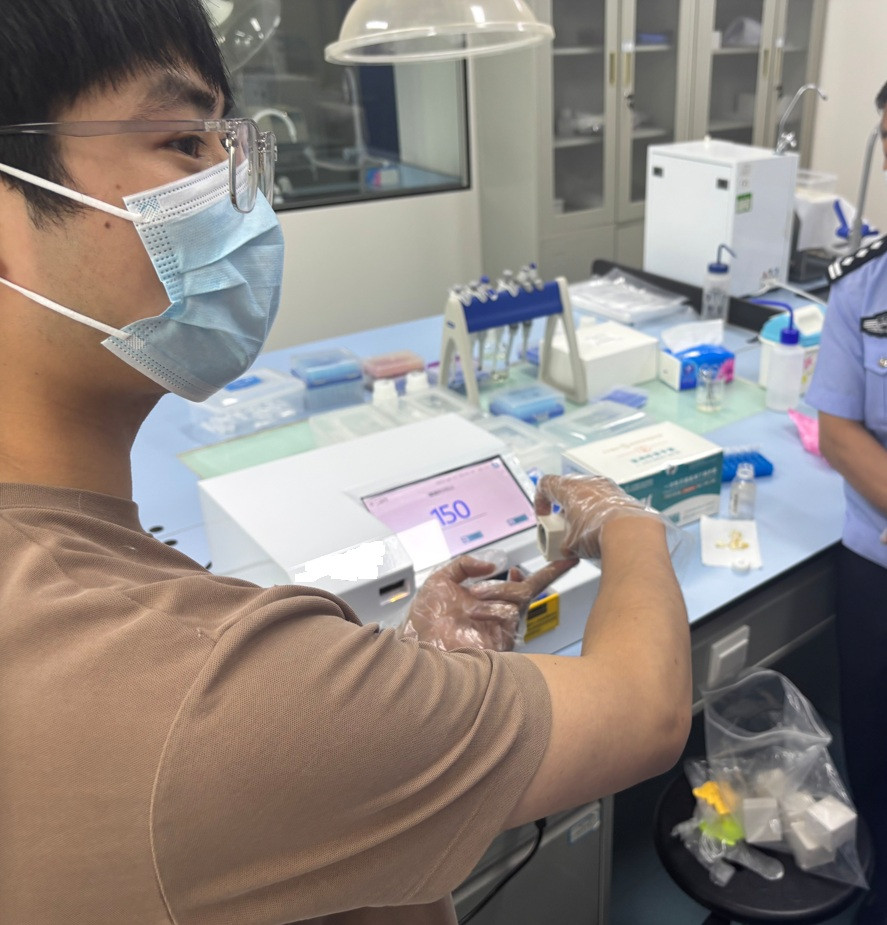

Validated Performance: Official Ministry of Public Security Test Report

The performance and reliability of this system are not merely claimed; they are officially certified. The instrument has undergone rigorous independent testing by the Ministry of Public Security (MPS) in China, a leading authority in forensic science and technology. The official MPS Test Report provides forensic validation of the system's key metrics, including grinding efficiency, powder consistency, and its impact on downstream DNA yield. This official certification offers laboratories independent verification and confidence that the technology meets the exacting standards required for forensic casework and is a reliable tool for producing court-admissible results.

Independent Verification of Key Performance Metrics

The validation data within the test report provides a quantitative, side-by-side comparison of the automated system against traditional manual methods. Key performance metrics such as total processing time, particle size distribution of the resulting powder, and, most importantly, the comparative DNA yield from subsequent extractions are clearly documented. This data demonstrates that the automated process not only saves significant time but also consistently produces a finer, more homogeneous powder that leads to higher and more reproducible DNA recovery, especially from challenging, low-yield samples.

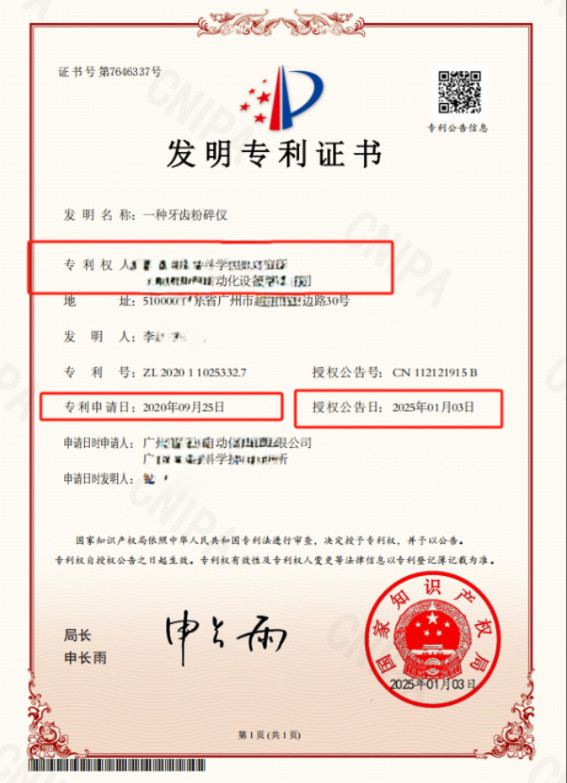

Innovation Protected: Our Patented Grinding Technology

The core mechanism that enables this instrument's performance is a unique and protected innovation. The patented technology encompasses the specific mechanical design of the grinding motion, the sealing mechanism of the disposable cassette, and the integration of the cooling system. This intellectual property represents years of research and development focused on solving the specific problems of forensic sample preparation. The patents, including both utility and design patents, safeguard this innovation and attest to its novelty and engineering excellence in the field of forensic science equipment.

Patent Details and Unique Engineering Features

The system is protected under multiple patents. The unique engineering features ensure complete and even pulverization without creating heat hotspots. The sealing mechanism of the disposable cassette employs a proprietary locking design that guarantees a perfect seal during the high-force grinding process, preventing any leakage of material or ingress of contaminants. These patented elements work in concert to deliver the consistent, high-quality results that define the instrument's performance.

Simple & Standardized Workflow: From Sample to Powder in Minutes

Adopting new technology should simplify laboratory operations, not complicate them. The workflow for this automated grinder is designed to be intuitive and easily integrated into existing Standard Operating Procedures for sample preparation. The process requires minimal decision-making from the analyst, reducing human error and ensuring that every sample is treated identically. This standardization is key to achieving reproducible results across different operators and over time, which is a fundamental requirement for any accredited forensic testing process.

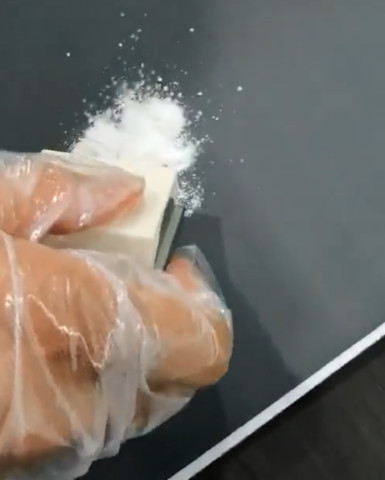

Step-by-Step Visual Guide to the Automated Grinding Process

The process is straightforward. First, the pre-cleaned tooth or bone fragment is placed into a sterile, disposable grinding cassette, which is then securely closed. Second, the sealed cassette is inserted into the designated slot in the instrument's grinding chamber. Third, the operator uses the touchscreen interface to scan the sample's barcode and initiate the automated grinding cycle with a single touch. The machine handles the rest. Finally, upon cycle completion, the cassette is removed. The technician then opens it in a clean workspace and directly transfers the fine, homogeneous powder into a labeled centrifuge tube, ready for the addition of lysis buffer and the commencement of DNA extraction.

Support, Training & Warranty

Our commitment to customer success extends far beyond the delivery of the instrument. We provide a comprehensive support package designed to ensure rapid installation, effective user training, and long-term, reliable operation. From the initial setup to ongoing technical assistance, we partner with your laboratory to maximize the value and productivity gained from this advanced technology.

On-Site Installation and Comprehensive Operator Training

Upon delivery, a qualified engineer will perform on-site installation and calibration of the instrument. This is followed by comprehensive operator training conducted by an application specialist. The training includes a hands-on demo with actual sample materials, detailed review of the Standard Operating Procedures (SOP) provided, and guidance on troubleshooting common alerts. This ensures that your team is confident and proficient in using the system from day one.

Extended Warranty and Dedicated Forensic Support

The instrument is backed by a standard manufacturer's warranty, with options for extended coverage. We offer dedicated forensic technical support via phone and email, with access to specialists familiar with the challenges of DNA recovery from hard tissue. Optional service contracts are available, which include scheduled preventive maintenance visits by field service engineers to ensure the instrument remains in optimal condition, guaranteeing its readiness for your most important casework.

Get a Quote

Contact our sales staff, tell us your needs, and we will provide you with the most suitable solution.

Contact Now