Restore Peak Performance in Your DNA Sequencer

Maintaining the analytical precision of your capillary electrophoresis instrument is non-negotiable in forensic DNA analysis. Over time, the delicate internal surfaces of the capillary array can accumulate residues from separation polymers and sample matrices. This buildup gradually degrades resolution and data quality, potentially impacting the reliability of STR profiles crucial for casework. A dedicated capillary regeneration protocol is not merely an option but a fundamental component of a robust quality assurance program, ensuring your genetic analyzer consistently delivers the high-fidelity data that the justice system depends on.

Recognizing the need for intervention is key. Common indicators that your system may benefit from capillary regeneration include a noticeable decline in peak height or resolution, increased baseline noise, inconsistent migration times between runs, or a rise in failed samples requiring re-injection. These symptoms suggest that the capillary's inner walls are no longer providing an optimal environment for DNA fragment separation. Addressing these signs proactively with a proven regeneration solution can prevent more severe performance drops and safeguard your laboratory's operational continuity and throughput.

Why Capillary Regeneration is Critical for Forensic Workflows

In a forensic DNA laboratory, the integrity of every electropherogram is paramount. Capillary electrophoresis systems are the workhorses that generate the final DNA profiles used for identification and comparison. When capillary performance wanes, the risk of allelic dropout, split peaks, or poor low-copy number detection increases. This can lead to ambiguous results, necessitating time-consuming re-analysis and potentially delaying investigations. Implementing a regular capillary regeneration regimen directly supports the generation of court-admissible data by preserving the original specifications and sensitivity of your instrumentation.

Signs Your Capillary Array Needs Regeneration

Laboratory personnel should monitor several key performance metrics. A gradual increase in current or pressure required to achieve flow, or a shift in the elution time of internal size standards, are technical signs of fouling. Visually, electropherograms may show broader peaks or elevated background fluorescence. Proactive maintenance, guided by these indicators, is far more cost-effective than reacting to a complete analytical failure. Integrating routine performance checks with a scheduled capillary care plan allows labs to predict and plan for maintenance, minimizing unexpected instrument downtime during critical casework.

The Science Behind Our Advanced Regeneration Chemistry

The efficacy of a capillary regeneration solution hinges on its chemical formulation. It must be powerful enough to thoroughly dissolve and remove hardened polymer residues and biological contaminants, yet gentle enough to preserve the fused silica's surface chemistry and inner diameter. Our proprietary chemistry is engineered to break down cross-linked polymer matrices without compromising the capillary wall's integrity. This balance is essential; overly aggressive cleaners can etch the silica, permanently altering electroosmotic flow and ruining the array, while weak solutions will not restore performance.

This advanced formulation operates through a combination of specific surfactants and cleaning agents designed to target forensic analysis byproducts. It effectively strips away accumulated debris, effectively "resetting" the capillary's interior to a state much closer to its original condition. This process helps restore uniform electroosmotic flow and consistent sample migration, which are the foundations of precise fragment sizing and accurate allele calling in DNA profiling.

Proprietary Formulation for Superior Polymer Removal

The challenge in capillary regeneration lies in the tenacity of used separation matrix, which can form a stubborn coating. Our solution utilizes a tailored blend of components that penetrate and solubilize these residues without requiring excessive pressure or prolonged incubation times. This efficient removal process is critical for forensic labs operating on tight schedules, as it reduces the instrument's offline period for maintenance, allowing scientists to return to sample analysis more quickly with confidence in their system's renewed capability.

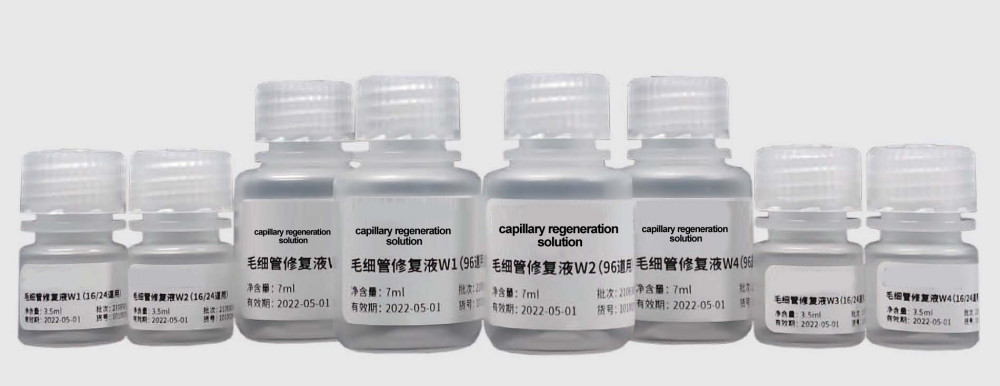

Compatible with Major CE Instrument Platforms

Compatibility is a cornerstone of our product design. Our capillary regeneration kits and protocols are rigorously validated for use with mainstream capillary electrophoresis platforms prevalent in forensic laboratories, such as the Applied Biosystems series of genetic analyzers. This ensures that laboratories can integrate this maintenance step seamlessly into their existing standard operating procedures. The protocol is designed to work within the instrument's own software and fluidics framework, providing a familiar and safe process for technicians to follow, thereby reducing the risk of user error during the crucial maintenance phase.

Streamlined Protocol for Minimal Downtime

We understand that instrument availability is vital. Our capillary regeneration protocol is designed with efficiency in mind, providing a clear, step-by-step process that minimizes operational interruption. The procedure typically involves a sequence of flushing steps with specialized solutions, followed by conditioning and equilibration. Each stage is precisely defined, with recommended durations and pressures to ensure thorough cleaning without stress on the capillary array or the instrument's fluidic system. This structured approach demystifies the maintenance process, making it an accessible task for laboratory staff.

Following the regeneration steps, a performance verification run is strongly recommended. This involves running a known standard, such as a DNA sizing ladder, through the regenerated array. The resulting data should be compared against established baseline metrics for the instrument. Parameters like peak symmetry, resolution between specific size fragments, and overall signal intensity provide quantitative evidence of the regeneration's success. Documenting this verification is also an excellent practice for the laboratory's quality management system, providing a record of instrument maintenance and performance status.

Integrating Regeneration into Your Preventive Maintenance Schedule

To maximize instrument lifespan and data consistency, capillary regeneration should not be a reactive measure but a planned preventive activity. The optimal frequency depends on your laboratory's sample volume and type. A high-throughput lab processing numerous casework samples may require regeneration more frequently than a lab focused on research. A best practice is to establish a schedule based on the number of injections or a regular time interval, such as quarterly, and adjust based on the performance monitoring signs discussed earlier. This proactive integration into your lab's calendar ensures sustained data quality and avoids the productivity loss associated with emergency repairs or capillary replacement.

Essential Companion Products for Capillary Care

A comprehensive capillary maintenance strategy extends beyond regeneration. High-purity wash solutions and buffers are used routinely between runs and during deeper cleaning cycles to prevent initial residue accumulation. These reagents are formulated to be free of particulates and contaminants that could themselves contribute to capillary clogging or background fluorescence. Using such high-grade consumables as part of daily operations is the first line of defense in preserving capillary health and extending the time between major regeneration procedures.

For validation and troubleshooting, performance verification kits are indispensable. These kits contain standardized DNA ladders or test fragments that produce a characteristic electropherogram when the capillary array and detection system are functioning correctly. Regularly running these verification tests provides an objective, data-driven snapshot of instrument health. When performance begins to drift, the data from these kits can help diagnose whether the issue lies with the capillary array, the polymer, the optical system, or another component, guiding the most effective corrective action.

Replacement Capillary Arrays and Polymers

Even with exemplary care, every capillary array has a finite operational lifespan. When regeneration and standard cleaning no longer restore data quality, it indicates the need for a replacement capillary cartridge. Sourcing high-quality, OEM-compatible replacement arrays ensures that your instrument will return to its original performance specifications. Similarly, using reliable, batch-consistent separation polymers is critical. Inconsistent polymer viscosity or composition can lead to poor injection, irregular migration, and suboptimal peak morphology, undermining all other maintenance efforts. A holistic approach to consumables is key to system reliability.

FAQs: Capillary Regeneration and Maintenance

How often should I regenerate my capillaries?

There is no universal answer, as it depends heavily on workload and sample type. A laboratory processing a high volume of challenging samples, like low-quality or inhibited DNA extracts, might need to regenerate every 200-300 injections. A lab with a lighter, cleaner sample load might extend that to 500 injections or more. The most reliable method is to follow the instrument's performance metrics and establish a lab-specific schedule. Starting with a conservative interval and adjusting based on observed data quality is a prudent strategy.

Can regeneration fix physically damaged capillaries?

No, capillary regeneration is a chemical cleaning process designed to remove contaminants. It cannot repair physical damage such as cracks, fractures, or severe bending in the fused silica tubing. These types of damages typically require complete replacement of the capillary array. Regeneration addresses performance degradation caused by fouling and residue buildup, not structural failure of the capillary itself.

What data quality improvements can I expect post-regeneration?

Following a successful regeneration, users typically observe a restoration of peak height and morphology, leading to improved signal-to-noise ratios. Resolution between closely sized DNA fragments often sharpens, which is critical for accurate allele designation in complex mixtures. Migration times should become more consistent, reducing run-to-run variability. These improvements collectively enhance the confidence in data interpretation and can reduce the need for sample re-injection, thereby increasing laboratory efficiency.

Your Partner in Forensic Laboratory Sustainability

Responsible laboratory management encompasses both scientific rigor and operational sustainability. Proactive instrument maintenance, including capillary regeneration, is a direct contributor to environmental stewardship. By significantly extending the usable life of expensive capillary arrays—and by extension, the genetic analyzer itself—laboratories dramatically reduce electronic waste. Choosing to regenerate and maintain rather than prematurely discard aligns with green laboratory initiatives and demonstrates a commitment to resource efficiency.

This approach is also profoundly cost-effective. The expense of a regeneration kit is a fraction of the cost of a new capillary array. Implementing a regular maintenance schedule that includes regeneration can defer replacement costs for many months or even years, offering substantial savings on consumables. These funds can be reallocated to other critical areas of the laboratory, such as validation studies, staff training, or new technology evaluation.

Contact Our Technical Support for a Custom Maintenance Plan

Every forensic DNA laboratory has a unique workflow and set of challenges. Our technical support team, staffed by scientists with direct experience in forensic capillary electrophoresis, is ready to assist. We can help you analyze your performance data, recommend a tailored regeneration and maintenance schedule, and provide troubleshooting guidance. Contact us to develop a proactive instrument care plan that ensures your laboratory achieves the highest levels of data reliability, operational efficiency, and fiscal responsibility.

Get a Quote

Contact our sales staff, tell us your needs, and we will provide you with the most suitable solution.

Contact Now